“Woe is we who try to store these lids.”

~

Mason jars are perfect in almost every way. The glass itself is strong and sturdy, rugged enough to throw in a backpack, thermally tolerant so it can be boiled for canning or be microwaved, yet elegant in a way that has allowed it welcome entry and display in the curated kitchens of modern day. The designers of the mouth famously made it so only 2 standard lid sizes would ever be needed, allowing future creators to run wild with the rest of the jar while still preserving interchangeability. For those in the world of engineering, this is the sort of interface design that dreams are made of.

But, like the perfect apartment which then has a neighbor who plays loud polka in the mornings, the storage of the lids is a constant annoyance.

Why? Because they do not stack!

Never have I been in a kitchen that dealt well with this issue. Piled in drawers, separated and impaled on some phallic item already in your kitchen, or replaced on the jars each time… none of these solutions are good.

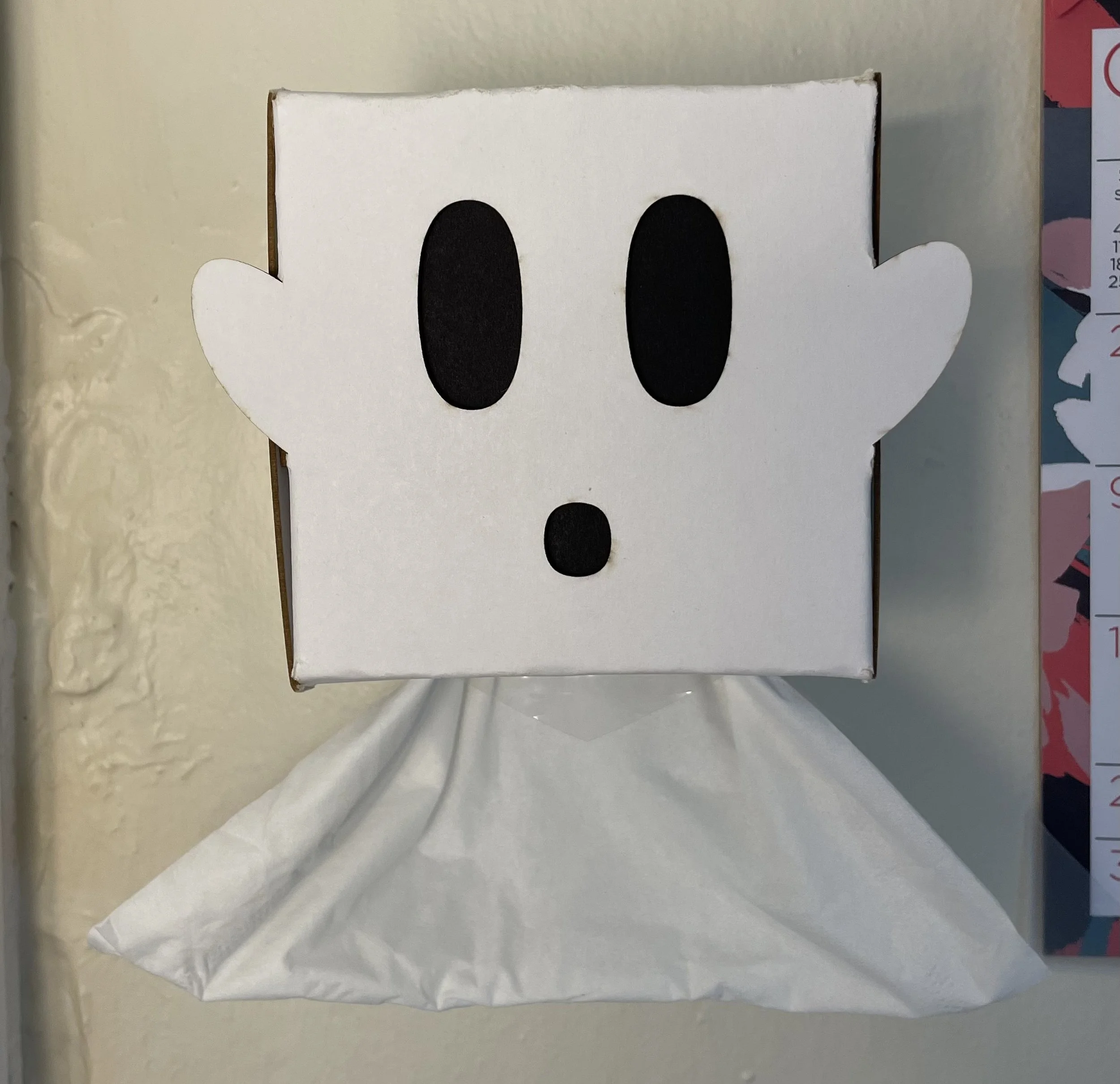

[Magnetic Mason Jar Lid Rack: enter stage left]

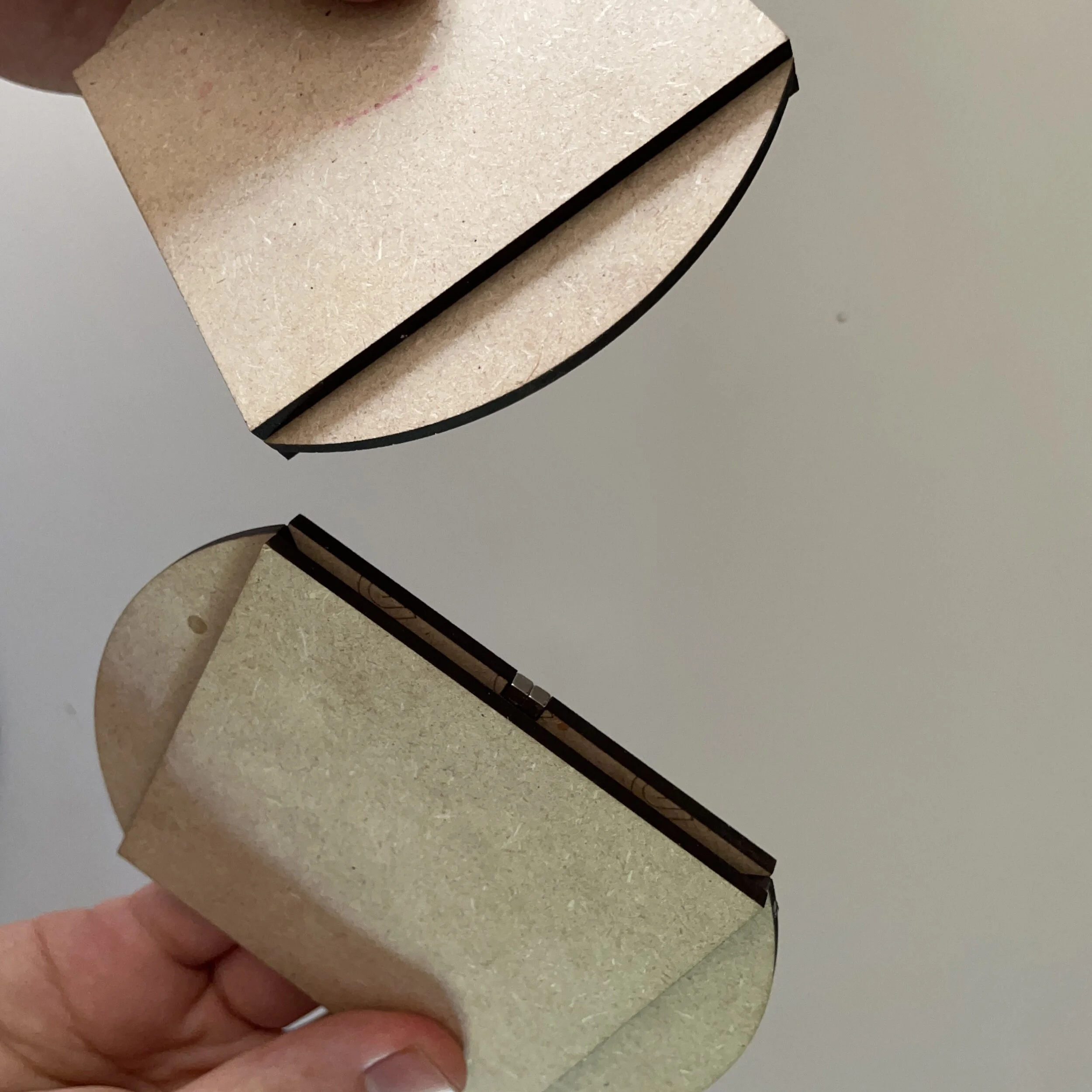

This storage rack takes advantage, as many of my creations do, of the lids being attractive to magnets. Their steel composure, both of the ring and the inside disc, can be held by the rare earth magnets embedded in this rack.

The rack itself is adhered to its host surface with 3m command strips, and can be placed in any orientation.

~

There is a peace that descends on a kitchen, really any space we inhabit, when a constant source of irritation has been soothed.

That has been my kitchen since the introduction of this rack, and maybe one day it will be yours as well.

~

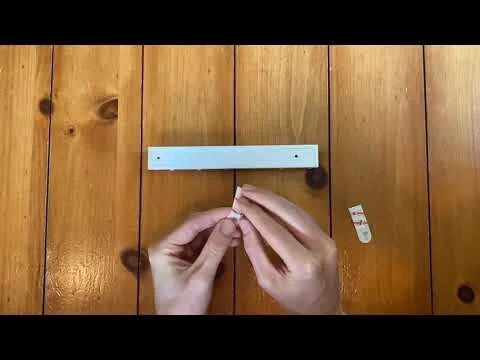

How to Install: https://youtu.be/xcTnlIblAuk

For a while I was 3D printing and selling this project, but it’s on hiatus for now. If I begin to sell it again, I’ll let folks know in my newsletter.